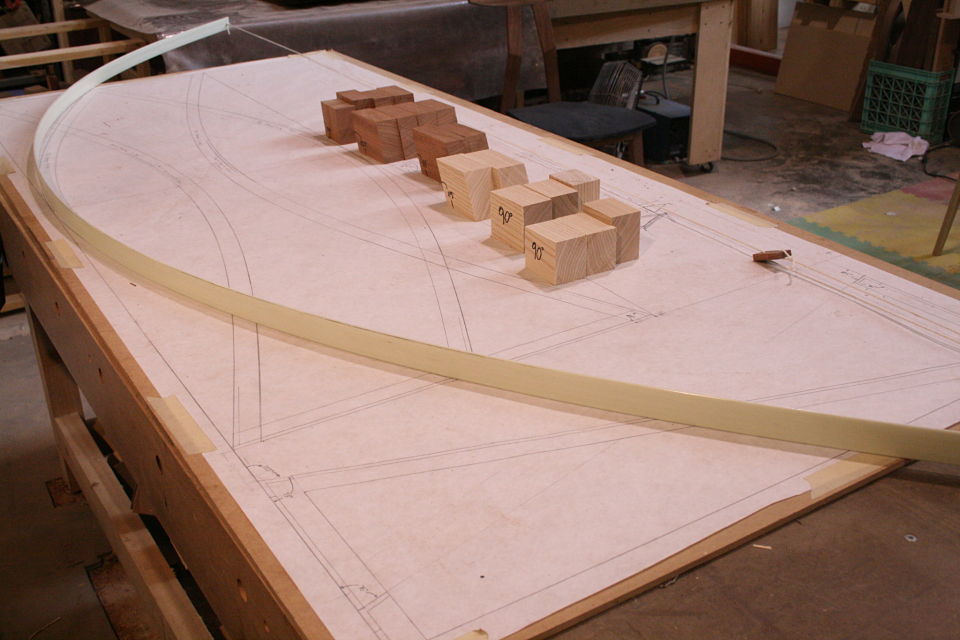

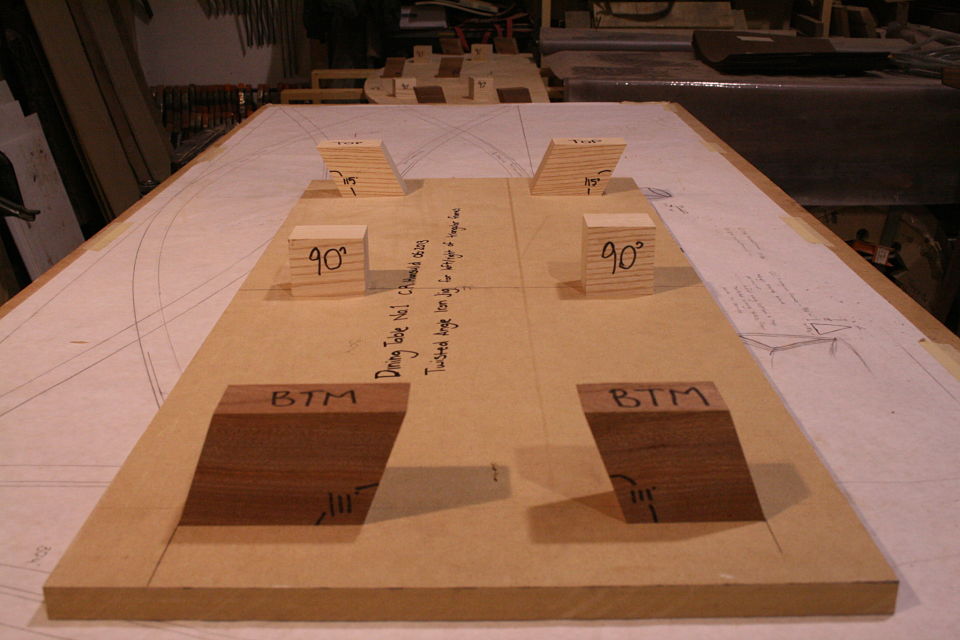

The slats have all been fit on Dining Table No. 1. After having steamed and twisted the 66 white oak slats they had a lot of water stains on the slats. The water stains were on the slats when they came out of the steam box, I can’t say for sure why but my hunch is I didn’t have them spaced out enough and/or condensation was dripping down onto the slats throughout the steaming process. In most cases I wouldn’t worry to much about it, just scrape and sand until clear. However the design called for the outside face of the slats to have a bandsawn texture, this meant I was going to have to find another way of removing the water stains.

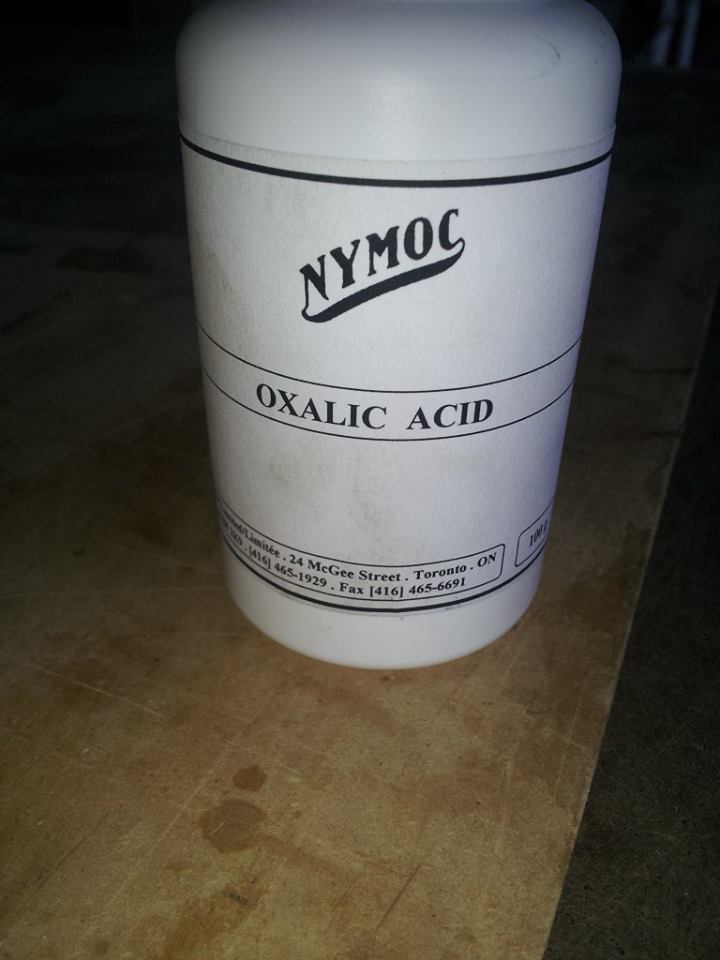

Some internet searching led me to find an organic compound solution, oxalic acid, which is a poison found in rhubarb. I ended up in what I can only best describe as a mad laboratory studio in the east end of Toronto where I purchased a 100g of the powder. Mixed roughly 10 parts water to 1 part Oxalic Acid I began scrubbing away at the stains with a wire brush. The test proved semi successful, although the stains were mostly gone the colour in the wood went with it leaving a sort of washed out dirty bleached look. It was undesirable for the finish I was looking to attain and meant going back to the drawing board.

With no real explanation as to why I thought it would work I decided to try and steam the stains out (last resort). Armed with my second hand iron and a wet clean rag I began steaming the water stained spots. Much to my disbelief the stains were lifting right out of the wood and actually transferring onto the rag. Some of the darkest spots took a couple tries but in the end I was left with clean (and wrinkle free) slats. I prepped them for finish by using the wire brush in line with the bandsaw marks to clean the slats and sanded a small chamfer on the edges. Few coats of wipe-on-poly later and I couldn’t be happier. As much as I had fun with my brief organic compound trial, I am thrilled that steam was the solution. Be it bending, twisting, fixing dents or removing water stains, steam is the trick.